Typical Applications

ARI is designed to detect defects such as:

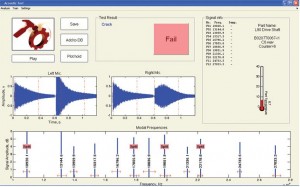

- Cracks

- Cavity

- Cold shuts

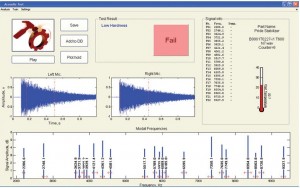

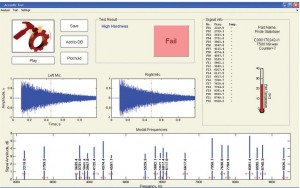

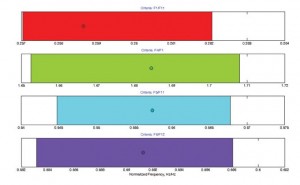

- Hardness deviations

- Low nodularity

- Residual stress

- Out-of-tolerance dimensions

Features

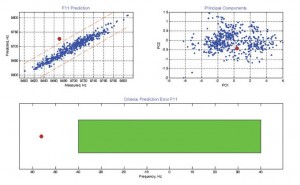

- High speed, accurate and repeatable measurements

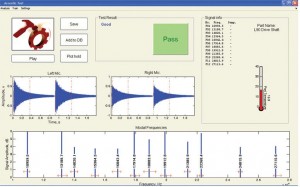

- Easy to use and user friendly interface

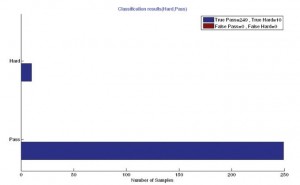

- Classification of parts based on advanced data modeling and multivariate statistics methods

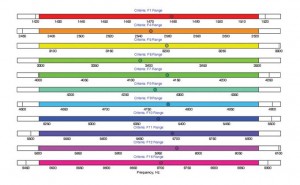

- Temperature compensation of resonant frequencies using infrared thermometer

- Automatic impact using dual electromechanical hammers with adjustable strike force

- Expandable impact unit to dual hammers to excite the part sequentially at different positions

- Input/Output control signals for trigger, alarm or other on-line process

- Dust-proof and weather resistant enclosure

- Customized fixture design with pneumatic control for part mounting

- Report generation, including statistical analysis

Applications of the ARI system in automobile industry can be summarized as:

| Material | Defect Type |

| Cast Iron | Nodularity, Hardness, Crack, Porosity, Cold Shot, Detached Layers |

| Steel | Crack, Hardness |

| Powder Metal | Crack, Raw Material Contaminants |

| Forged | Crack, Porosity, Missed Strike, Hardness, Heat Treatment |